Ethanol comes today as an essential product for the creation of sanitizing gel. This gel is used by everyone to keep our hands clean and avoid any contagion from Covid-19.

Most alcohol and liquor distilleries have this precious element that allows them to create products to keep surfaces clean and hands protected.

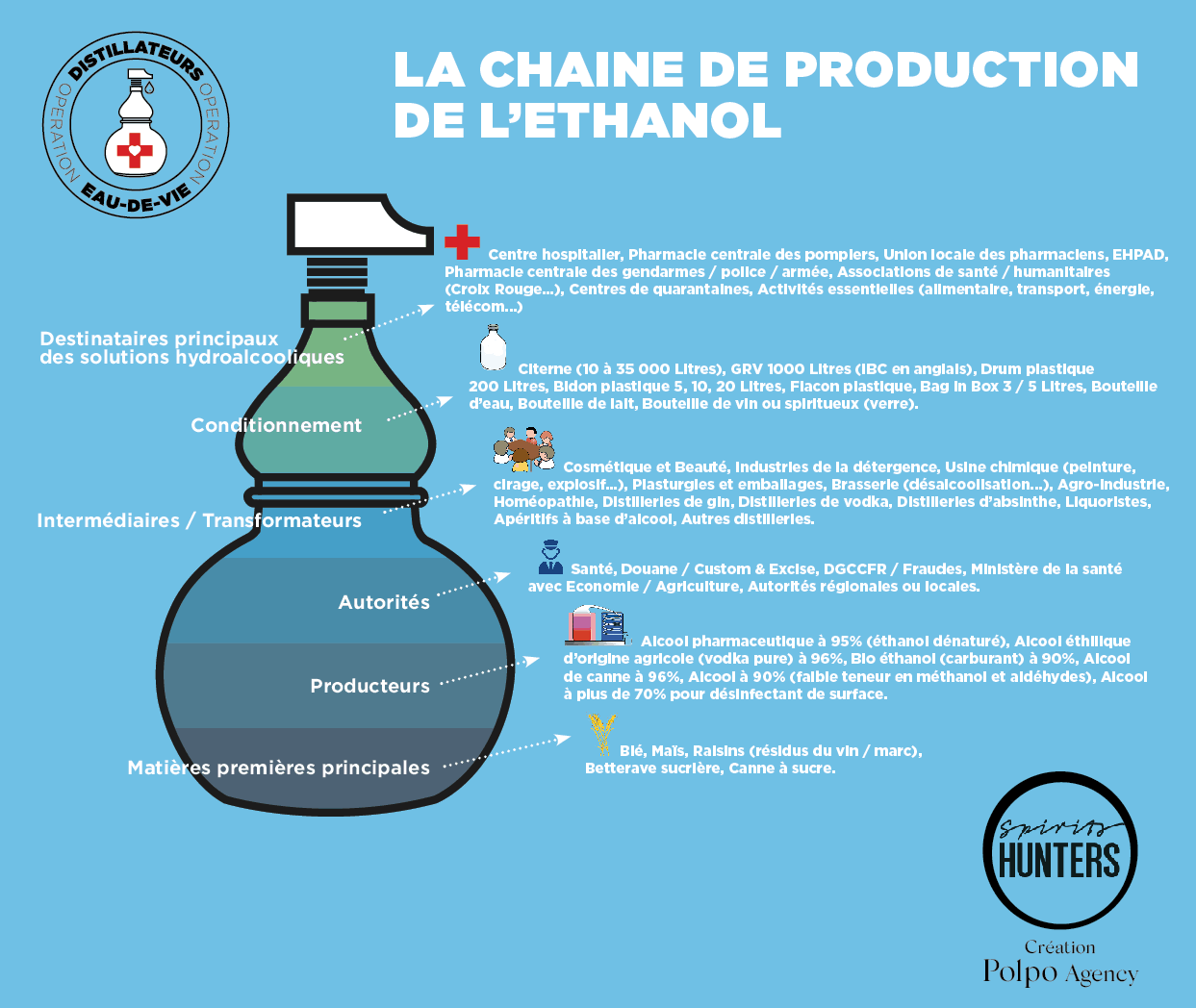

The following are the stages in the supply chain that lead from ethanol to the creation of the gel.

From left to right – From bottom to top.

Main raw materials: wheat, corn, grapes (wine/pomace residues), sugar beet, sugar cane.

Producers: pharmaceutical alcohol 95% (denatured ethanol). Ethyl alcohol of agricultural origin (pure vodka) 96%. Bioethanol (fuel) 90%, sugar cane alcohol 96%, alcohol 90% (weak content of methanol and aldehydes). Alcohol over 70% to disinfect surfaces.

Authorities: health, customs. Custom & Excise, DGCCFR / Fraud, Ministry of Health and Ministry of Economy / Agriculture, regional or local authorities.

Intermediaries / Processors: cosmetics and beauty, detergent industries, chemical factories (paint, waxing, explosives …), plastics and processing and packaging, brewery (de-alcoholization), agribusiness, homeopathy, gin distilleries, vodka distilleries, absinthe distilleries, liqueurs, alcohol-based beverages, other distilleries.

Packaging: cistern (10 to 35 000 litres), 1000 litre intermediate container, 200 litre plastic drum, 5, 10, 20 litre plastic jar, 3/5 litre bag in box, water bottle, milk bottle, wine or spirits bottle (glass).

Main receivers of hydro-alcoholic solutions: hospital, pharmacy, fire station, local union of pharmacists, nursing homes, central pharmacy of gendarmes / police / army, health associations / humanitarian (Red Cross), quarantine centers, essential activities (food, transport, energy, telecommunications …)

Don’t drink and drive. Enjoy responsibly.